Thermodynamic Pump Monitoring System

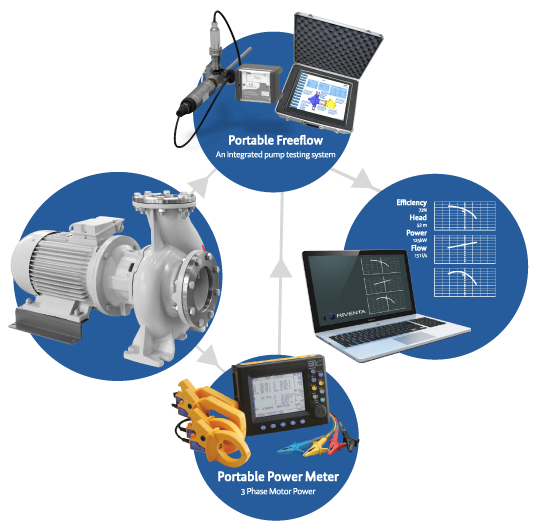

Our industry leading FREEFLOW portable thermodynamic pump testing system is an easy to use, self-contained thermodynamic instrument. It is one in our range of pump testing systems designed to measure pump performance characteristics on industrial pumps.

Why use a thermodynamic pump testing system?

Using our thermodynamic method remains the most accurate and powerful means of testing a pump. The portable system makes this easy to do in-situ, without compromise to safety or disruption to operations.

By simply measuring temperature and pressure across the pump, our precision technology calculates the efficiency and head of the pump (to an impressive accuracy of up to 0.5%). Then, by measuring the power consumed by the motor, we can calculate flow rate.

How the FREEFLOW portable works

Where existing pipework fittings are installed, an experienced technician can complete a typical pump test in less than two hours. A range of test points are taken at different flow rates, across the operating range of the pump. This data is used to plot performance curves of the pump under test.

Know what’s happening in your stations*

When we undertake Pump Monitoring and Optimisation, we manage, visualise and report on your pump assets and operational efficiency, providing real-time data and visualisations that will enable you to see what’s happening in your stations.

Each project focuses on the whole-life management of your assets and drives efficiency gains through dynamic optimisation using our easy-to-install pump monitoring kit.

*Essential for pumps 250kW or larger.

COMMONLY TESTED APPLICATIONS

- Split Case Pumps

- Blowers

- Fans

- Hydro Turbines

- Vertical Turbines

- Suitable for both low and high head applications

BASIC FEATURES

- Real-time measurement quality indicators

- Pump test wizard for test set-up guidance

- Industry standard analysis software

- Electrically isolated current transformers (to improve safety)

- Thermodynamic measurements meet ISO 5198

SYSTEM HIGHLIGHTS

- Easy to use, intuitive software

- Easily understand pump test results in clearly presented formats

- Readily interpret and evaluate the condition of a pump using easy to read performance curves

- Make comparisons with manufacturers curves and previous tests (where data is available) in a matter of minutes

Flexible Thermodynamic Pump Monitoring System

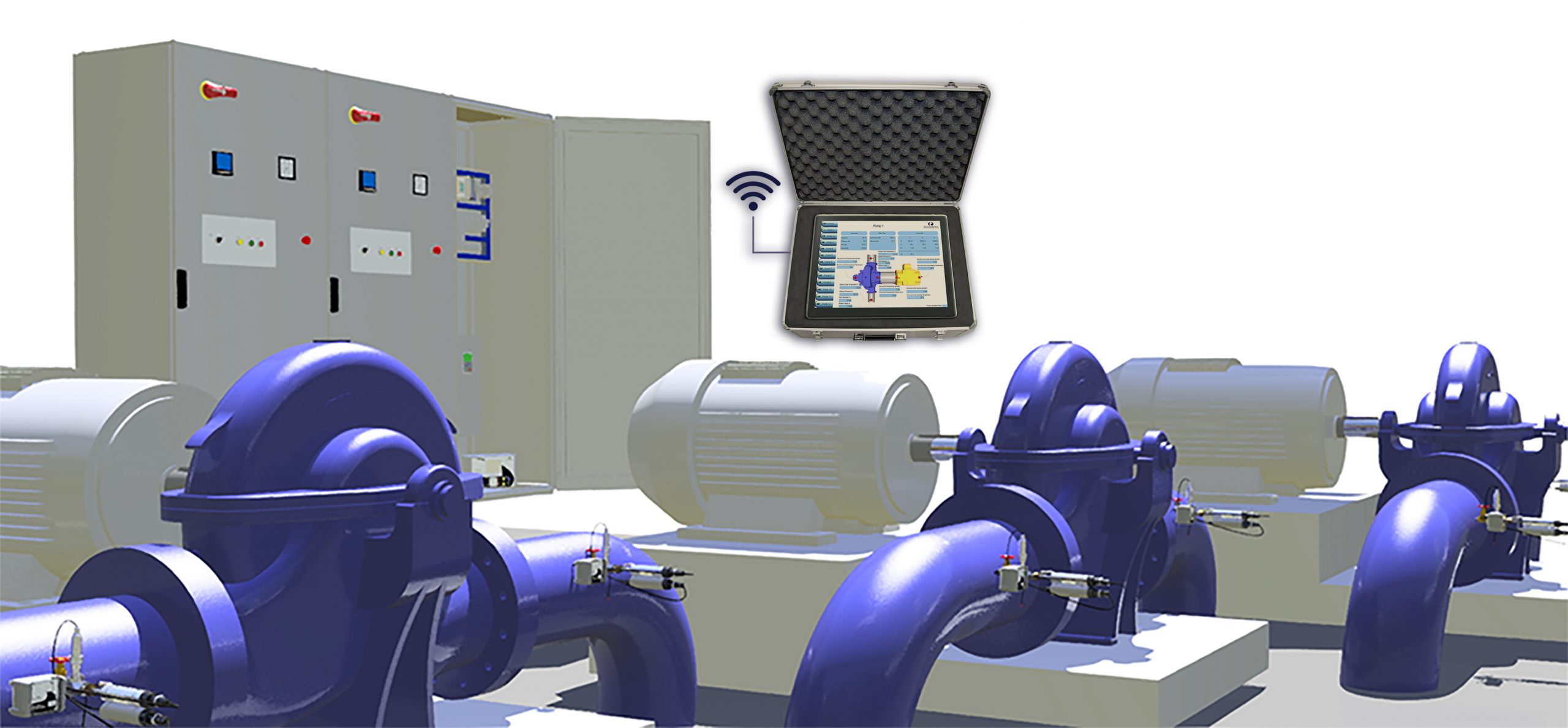

Our industry-leading FREEFLOWi4.0 thermodynamic pump monitoring system is easy to use, self-contained and wireless. It offers immense flexibility, highly suited to monitor pumps, blowers, fans and turbines at medium to large stations.

The system can be temporarily or permanently installed on-site, directly assessing actual operational performance, continuously gathering data and driving ongoing optimisation work.

Why use a thermodynamic pump monitoring system?

Pump system characteristics typically change with demand and station operation, particularly within larger pumping stations where absolute precision is necessary. Changes can be observed and controlled using a thermodynamic pump monitoring system over a set period.

Often hidden characteristics are discovered that can lead to major improvements in overall operating efficiency and asset lifecycle costs.

Make real-time pump optimisation a reality

Results can provide valuable data for real-time optimisation, and for planning capital expenditure and minimising whole-life costs. Monitoring can also reduce energy consumption, carbon emissions, hydraulic failure and premature wear.

How the FREEFLOWi4.0 works

Because a pump is usually part of a dynamic system, its contribution will vary with demand and system characteristics.

Our FREEFLOWi4.0 system can monitor hydraulic performance and pump efficiency. In conjunction with our operator interface software, the real-time effectiveness of each pump can be evaluated, and accurate data generated to make optimisation happen.

COMMONLY TESTED APPLICATIONS

- For medium to large pumping stations with typical pump size of 50kW and above

SYSTEM COMPONENTS

- One FREEFLOWi4.0 pump monitor

- One set of precision temperature transducers

- One 10-bar suction pressure transducer

- One 20-bar delivery pressure transducer

- One power measurement system (LV/HV)

- One touch screen local operator panel

- Two insertion glands per pump

SYSTEM HIGHLIGHTS

- Works with any high energy pump

- Enables motor efficiency to be measured using our patented technology

- Measures individual pump efficiency and flow rate

- Supports planned maintenance programmes by tracking reduction in pump efficiency

- Trends data to predict the most cost-effective time for pump replacement, refurbishment, coating or other remedial maintenance

- Provides pump head, flow, efficiency, power and motor efficiency

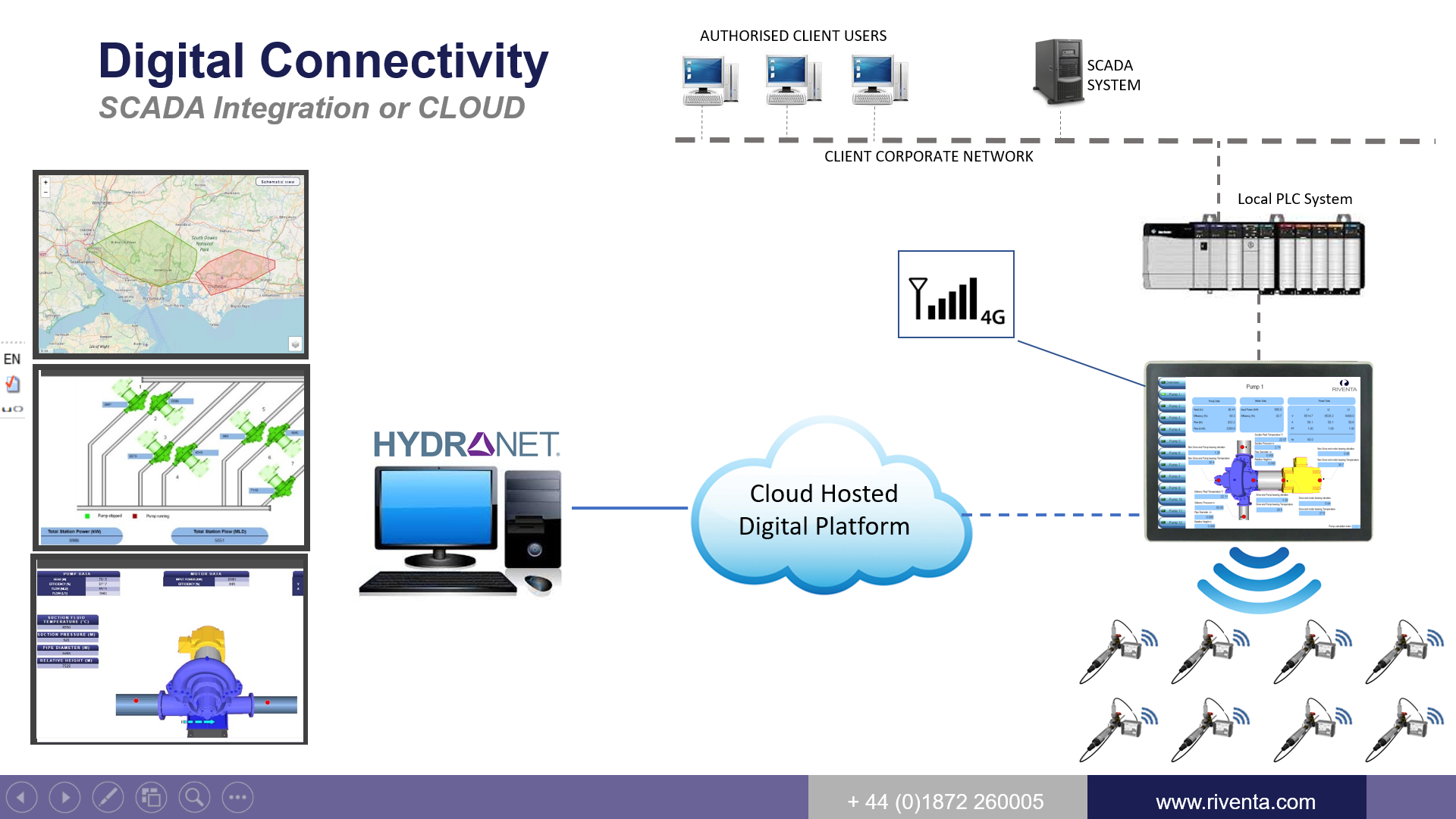

- Integrates with SCADA, standalone or web-access (security assured)

- Delivers the following real-time data, which are the building blocks of optimisation: pump efficiency (%), motor power (kW), flow rate (l/s) and pump head (m).

- The following measurements are taken: hydraulic measurement (differential temperature, suction pressure, discharge pressure), electrical power measurement (kW), asset performance information and motor efficiency measurement (%).

- Captures, processes and provide data to managers and operators via our interface software. Every minute of the day and night, enhanced information is made available from FREEFLOW to improve station efficiency and reduce operating costs.

HydraNET

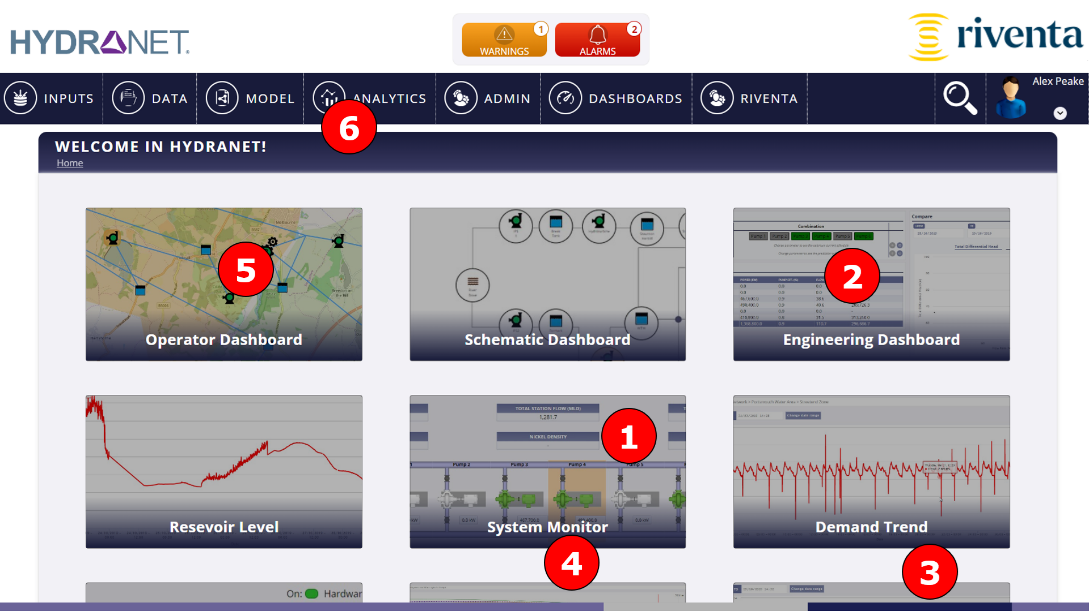

HydraNET – Real-Time Decision Support Software WorkStation to Unlock Hidden Efficiency Across Your Entire Network

Riventa HydraNET transforms how you manage your pumps by using real-time data and intelligent algorithms to automatically schedule operations for maximum efficiency. Whether you’re aiming to cut energy costs, extend equipment lifespan, or boost system reliability, HydraNET delivers the insight and control you need to run smarter, leaner, and more sustainably.

Key features:

- System Monitor

- Pump Scheduling

- Historical Data

- Curves and OEMs (Maintenance Prediction)

- Schematic + Map

- Auto-Reporting (Capital & Operational)

Why Use HydraNET

- Optimises pump scheduling by automatically selecting the most efficient pump or combination based on real-time performance data

- . Analyse system demand and adapt pump operation accordingly

- Historical Data

- Reduces energy consumption and electricity costs by identifying underperforming or energy-wasting pumps

- Extends pump lifespan by avoiding inefficient operations and overloading

- Continuously visualise pump efficiency, energy usage, and savings in real time through intuitive dashboards

- Supports sustainability goals by improving operational efficiency

- Delivers fast ROI through cost savings and improved asset utilisation

- Generate performance reports for audits and maintenance planning

- Alert operators of abnormal performance or system faults

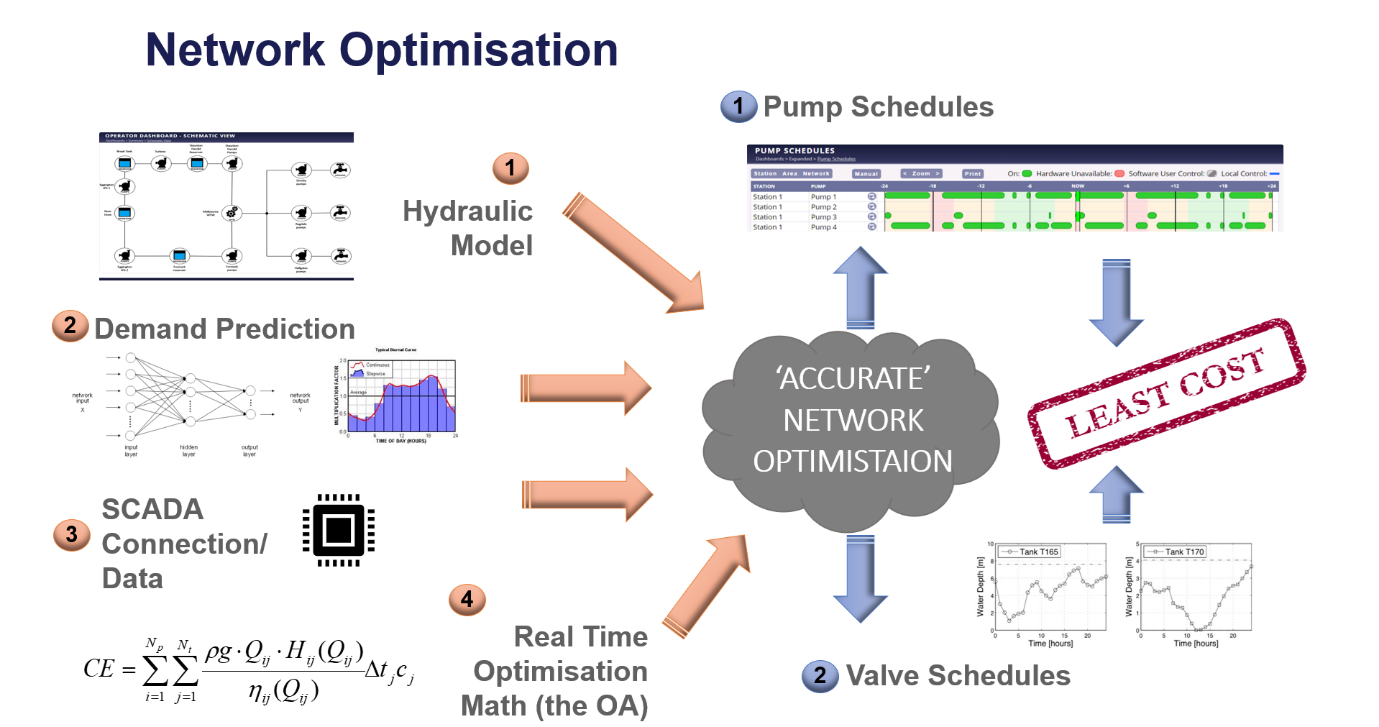

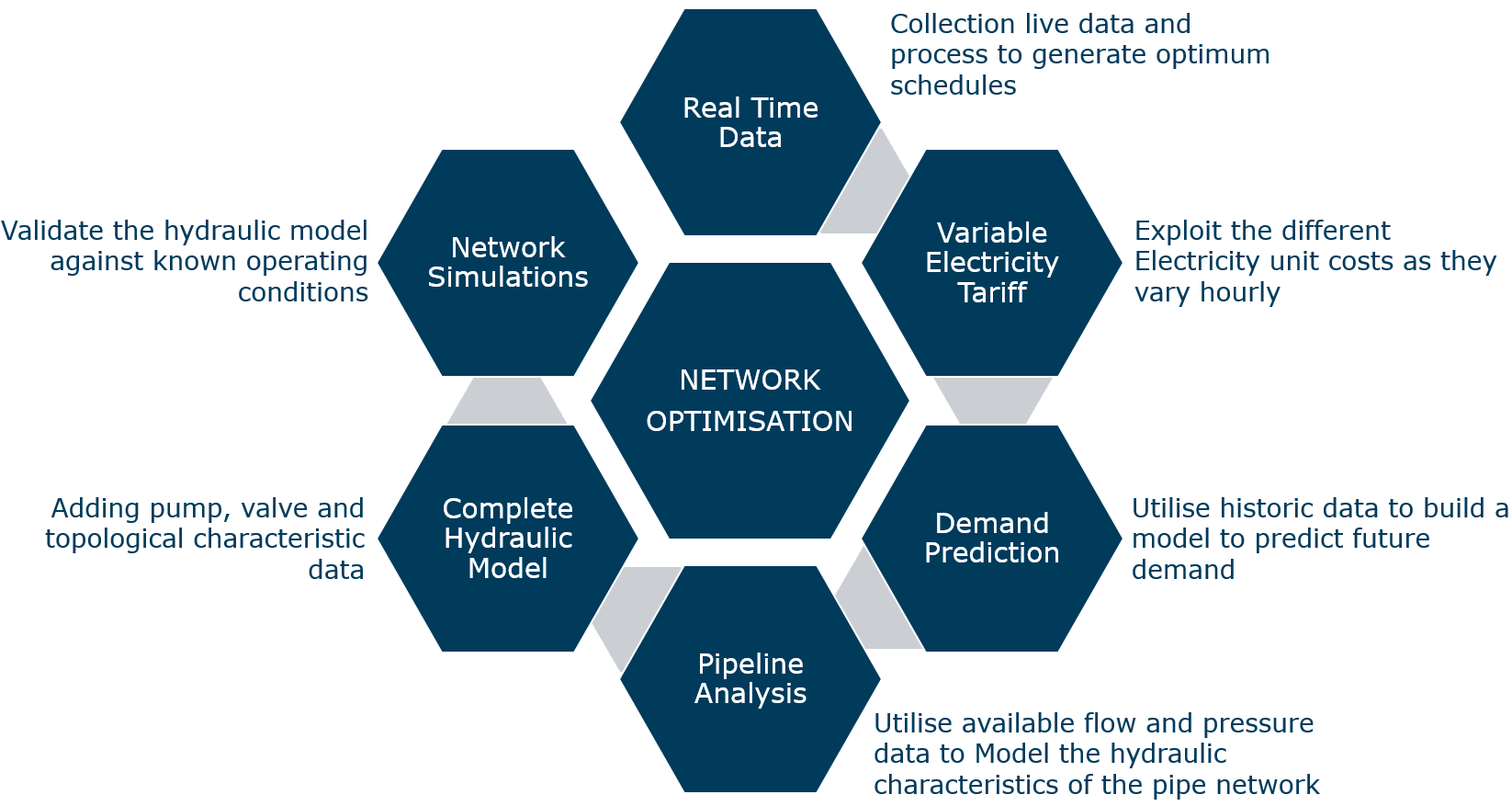

Network Optimisation

The purpose of HydraNET Network Optimisation is simple. It ensures your entire pumping system works in perfect harmony. By analysing real-time performance across all assets, HydraNET identifies the most energy-efficient combinations, minimises wastage, and adjusts operations dynamically to meet changing demand. It’s not just about saving power; it’s about gaining full control over your network, reducing operating costs, and achieving performance you didn’t know was possible.

Network Optimisation utilises data inputs such as tariffs, storage tank levels, demand prediction, and hydraulic conditions to generate an optimal schedule for the next 24-48 hours, achieving a minimal cost given any network constraints.

Predict demands, have a hydraulic model, and use some math to calculate the least cost solution over 48 hours; simulated every 15 minutes

Can provide an offline schedule (decision support, open loop) or an online system directly controlling infrastructure (real-time, closed loop)

Test Rig & ISO17025 Accredited Calibration Facility

Supply Records

| Project Title | Year |

| 1. Pilot Project Application for Pump Thermodynamic Monitoring System with Energy Saving Solution by Operational Technology Services (OTS) Section at Nottingham Pump House, Kajang Pilot Project Approval No : AIS/OSD/OTS/TDU/2021 –(410) |

2021 |

| 2. Conditional Assessment for Water Treatment Plants for Year 2021 (Package 2) On-Site Pump Efficiency Test by Thermodynamic Method for 4 Pumping Stations Pump | 2021 |

| 3. Cadangan Langkah Mitigasi Jangka Pendek bagi Sistem Bekalan Air Negeri Perlis | 2021 |

| 4. Cadangan Kerja-Kerja Peningkatan Sistem Agihan Berkeutamaan Tinggi bagi Wilayah Iskandar Malaysia. Pakej 1 – Cadangan Pembangunan Stesen Pam Pengglak, Pencawang Elektrik TNB, Tangki Menara 4.54ML di Tangki Tebrau Sediada, Lot PTB 23472 Taman Abad dan Pemasangan Paip Air dari Bandar Scientek ke Layangkasa Serta Kerja-Kerja Berkaitan. | 2022 |

| 5. Sg. Langat 10MGD RWP Tests | 2023 |

| 6. Supply Riventa FFX to Kejuruteraan Yun Loong Sdn Bhd | 2023 |

| 7. Teluk Kepayang Ebara RWPs Performance Test | 2023 |

| 8. Salak Tinggi KSB RWPs Performance Test | 2023 |

| 9. Sg. Labu Grundfos TWPs Performance Test | 2024 |

| 10. Proposed Construction Works of New Treated Water Pumphouse, Stesen Suis Utama (SSU), Suction Tank, 1600mm DN MSCL Pumping Main from Sungai Selangor Phase 1 (SSP1) WTP to Bukit Mayong Balancing Reservoir and Other Associated Works | 2024 |