Unsupervised Machine Learning Vibration System

Value to our Customers

Our typical client experiences the following benefits from implementing our solution:

95% decrease in unplanned maintenance costs.

14% reduction in safety incidents

25% decrease in annual maintenance spend

5% decrease in environmental incidents

20% extension in average asset functional life

0.2115% revenue increase due to less down time and additional production time available.

Wireless Sensor

High Resolution Vibration: Sample rate of 26.7kHz,detectable FFT to 10kHz, and early bearing fault detection, this high-resolution sensor is over 10 times the resolution of most wireless sensors on the market and can identify early bearing faults similar to the portable collectors. High resolution data allows predicting failure months in advance—not hours or days like many of the low-resolution sensors out there.

Simple Installation and Setup: Power it up and the sensor searches for a gateway and automatically connects to the dashboard. Select the asset location from a smartphone or from the dashboard AI platform will use it’s robust database library of millions of machine tests to start its training.

Hourly Temperature and Overalls: Keep an eye on your assets in-between the detailed diagnostics. Watch trends, trigger notifications, stay informed of asset operations.

Why Mesh?

A Wirepas Mesh Network allows for a significant increase in range and self-healing capability—completely different from other mesh networks, wifi or Bluetooth. Each gateway and sensor can support up to 14 direct connections, but the real value is the scalability and network planning; Improving connection reliability, easing the requirements for gateway installation as your program grows. reliability, easing the requirements for gateway installation, and easily expand as your program grows.

Dashboard

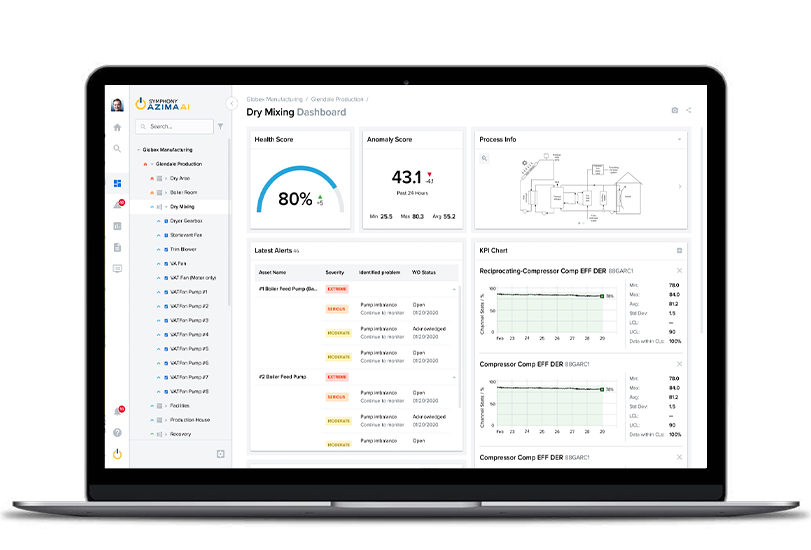

Remotely monitor your assets from anywhere in the world with dashboard.

Log in from your internet browser to view a calculated Health Score for every asset, group of assets, plant, or enterprise. From CEO down to the Asset Manager, and everyone in between, be alerted to emerging faults, risks to production, assigned prioritized actions, and business metrics. For wireless sensors, user can quickly see the health and status of each sensor and gateway to ensure your system is operational and healthy.

Walk-around devices

Take the data to the analyst and keep the analytical staff highly utilized in their skill.

It’s vibration data collectors and field analyzers are advanced vibration collection devices, but simple enough to place into the hands of everyday operators and field technicians. No need to be an analyst to gather quality, high-resolution data.

What you get with

It is ergonomically designed and uses Bluetooth® to wirelessly connect the Windows tablet controller to the data acquisition device, providing comfort and efficiency when performing vibration data collection. Modular design lowers the overall cost of ownership.

Supply Records

| Project Title | Year |

| 1. Sg. Langat 10MGD RWP No.2 Vibration Test | 2023 |

| 2. Emerging Technology – Pilot Project for Automated Diagnostic at Sg. Langat WTP – Vibration Condition Monitoring System – AI with Prescriptive Maintenance | 2023 |

| 3. Sibu Salim WTP – POC Vibration Analysis of TWP No.11 – TRIO Test | 2023 |

| 4. Tambirat Booster Station – POC Vibration Analysis of Pump No.5 | 2023 |

| 5. Batang Samarahan WTP – POC Vibration Analysis of Pump No.6 | 2023 |

| 6. Salak Tinggi KSB RWPs Vibration Test | 2023 |

| 7. Batu Kitang WTP – Pilot Project for Automated Diagnostic – Vibration Condition Monitoring System – AI with Prescriptive Maintenance | 2023 |

| 8. Nusajaya Booster Station – Pilot Project for Automated Diagnostic – Vibration Condition Monitoring System – AI with Prescriptive Maintenance | 2023 |

| 9. Sg. Labu Grundfos TWPs Vibration Test | 2024 |