Power Quality Monitoring System (PSD-PQM 1.0)

PSD-PQM 1.0 was developed through intensive field research and AI training, supported by calibration test rigs and real-world pilot deployments across multiple industries. The system is scalable, portable, and available for both fixed installation and handheld diagnostic use — ideal for utilities, oil & gas, water treatment, and manufacturing.

Power failures don’t just stop machines — they stall productivity, inflate costs, and risk critical safety. PSD-PQM 1.0 is a next-generation AI-powered power quality monitoring and motor diagnostics system that delivers real-time insights into your equipment’s electrical and mechanical health — all without stopping your operations.

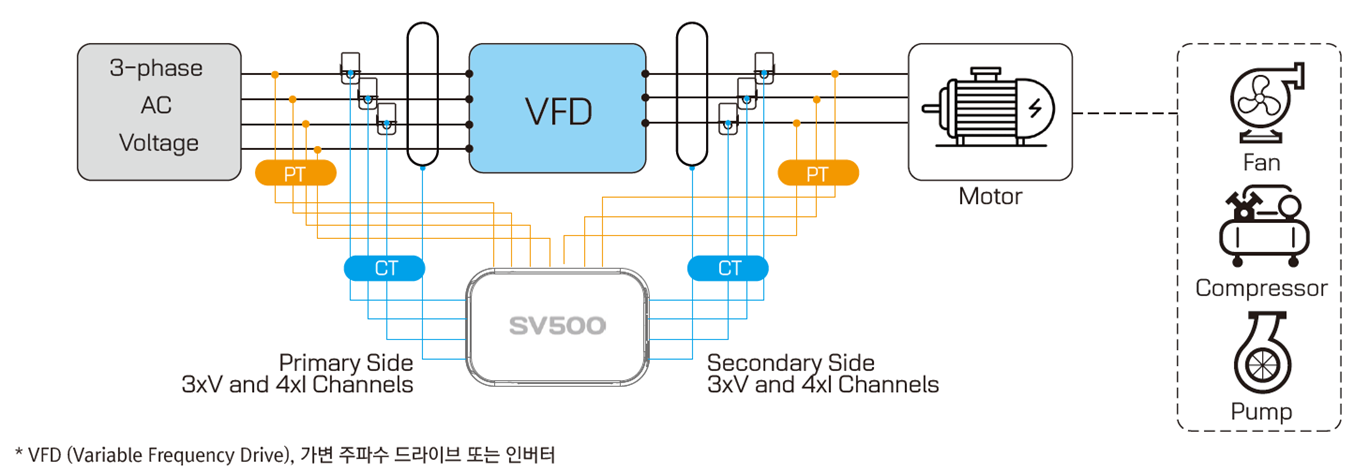

Using advanced signal processing and machine learning, PSD-PQM analyses current, voltage, frequency, and power factor trends from your inverters, motors, and pumps. It identifies potential issues such as harmonics, imbalance, overheating, cavitation, and mechanical misalignment — enabling predictive maintenance before failures occur

What’s Power Quality Analysis?

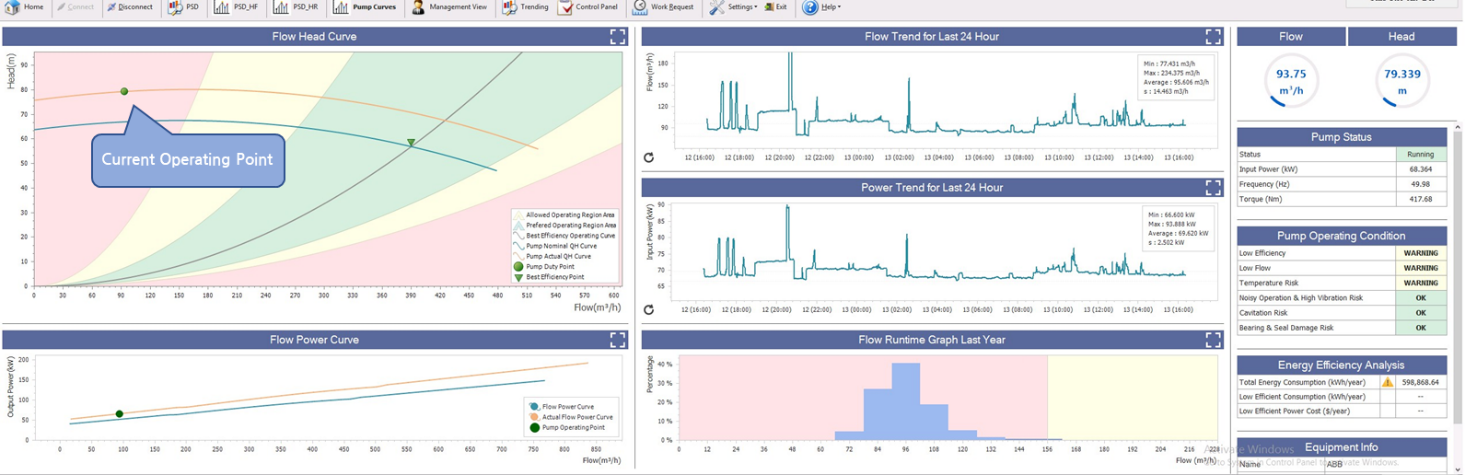

Power Quality Analysis refers to the continuous monitoring and evaluation of electrical parameters such as voltage stability, frequency fluctuations, harmonics, and energy efficiency. PSD-PQM 1.0 uses this data to detect disturbances, inefficiencies, and abnormalities across your system — helping you maintain optimal equipment performance and protect against unexpected downtime.

Why Use Power Quality Analysis?

- Avoid costly downtime by identifying faults early

- Extend asset lifespan through condition-based maintenance

- Reduce energy waste with accurate load and flow monitoring

- Prevent equipment damage from harmonics, overload, or unbalance

- Improve operational safety and power reliability

What PSD-PQM Can Do?

- Real-time diagnostics of inverter, motor, and pump performance

- Detect and predict faults using AI & machine learning

- Monitor power quality events (THD, voltage sag/swell, unbalance)

- Analyse rotor/stator health, misalignment, and bearing wear

- Provide efficiency mapping and load profiling for optimal operation

- Visual dashboards for trend analysis, event logging, and system alerts

- Operates with or without sensors (via current/voltage data taps)

Features, Applications & Highlights

| Features | Description |

| 📊 3-phase waveform analysis | 24-bit resolution at 8kHz sampling for high-precision signal capture |

| 🌀 Motor Current Signature Analysis (MCSA) | Detects rotor bar issues, air gap eccentricity, misalignment, etc. |

| 🧰 Electrical Signature Analysis (ESA) | Pump efficiency mapping, cavitation detection, overload warnings |

| ⚙ Real-time Web Dashboard | Visualise health, diagnostics, and alerts via cloud or on-premise |

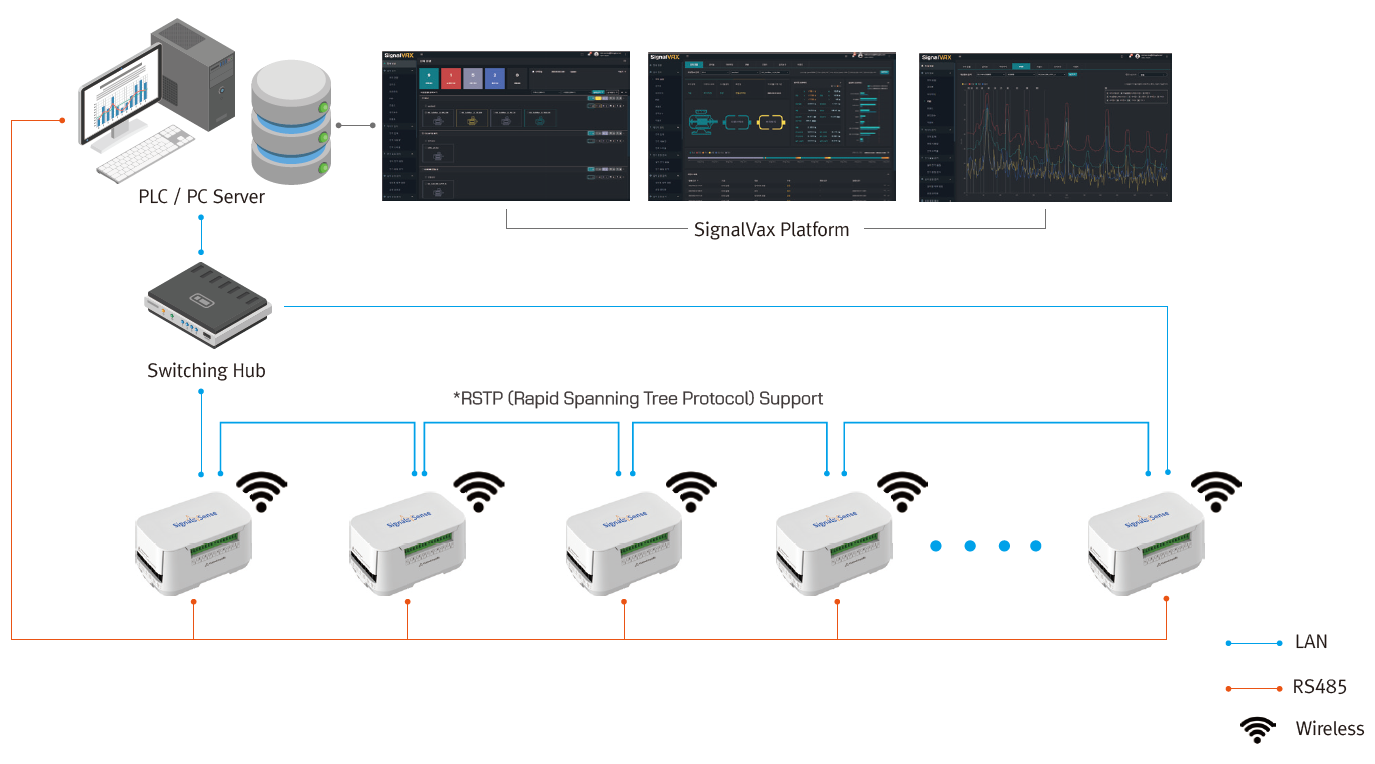

| 🌐 Communication | RS-485, Wi-Fi, LAN, RSTP-ready networking for secure industrial environments |

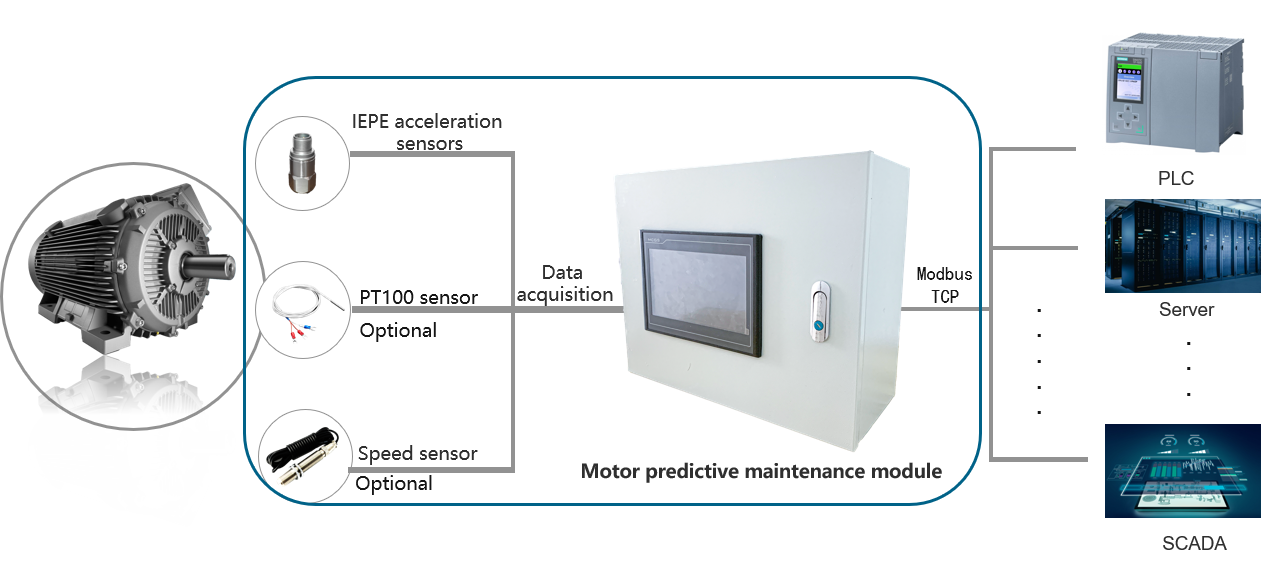

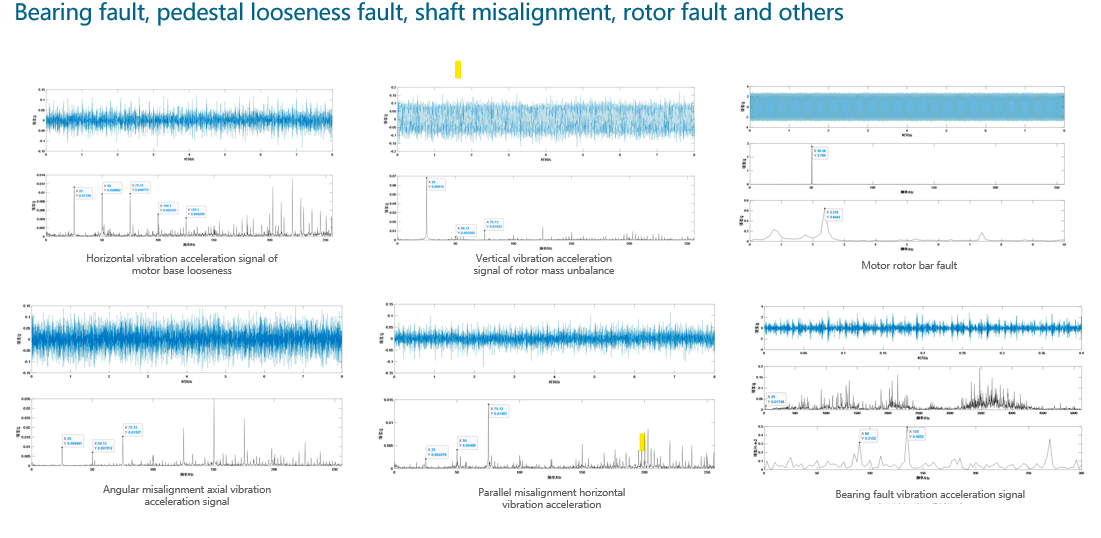

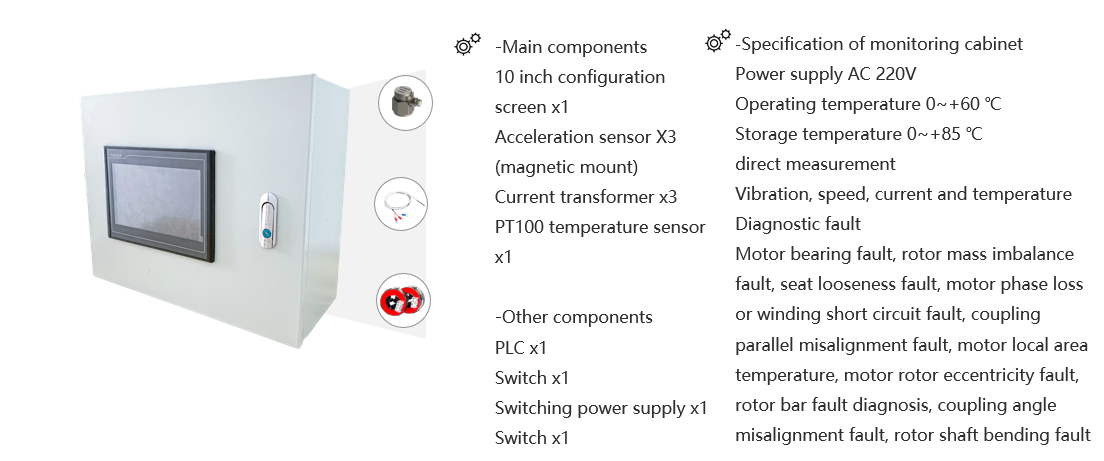

Intelligent Online Vibration Condition Monitoring System

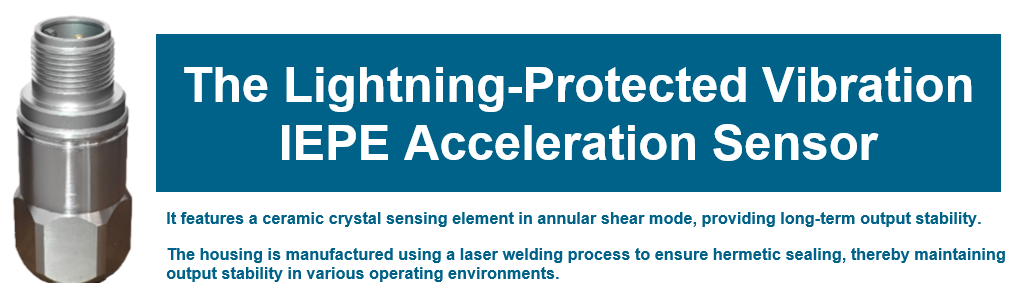

The Lightning-Protected IEPE Acceleration Sensor can be used for industrial motors and their driven equipment, such as pumps, fans, gearboxes, and bearing housings.

Advantages

NdFeB base for easy fixation

NdFeB base for easy fixation IP67 process, not afraid of harsh environment

IP67 process, not afraid of harsh environment Ultra small size and strong adaptability

Ultra small size and strong adaptability Low power consumption, optional battery powered

Low power consumption, optional battery powered Identify potential equipment failures and minimize downtime

Identify potential equipment failures and minimize downtime Maintenance based on equipment status to reduce costs

Maintenance based on equipment status to reduce costs Remote condition monitoring to improve personnel safety

Remote condition monitoring to improve personnel safety

Predictive Maintenance System

Built-In Diagnosis Model

Standard Standalone / Wall-Mounted HMI Panel

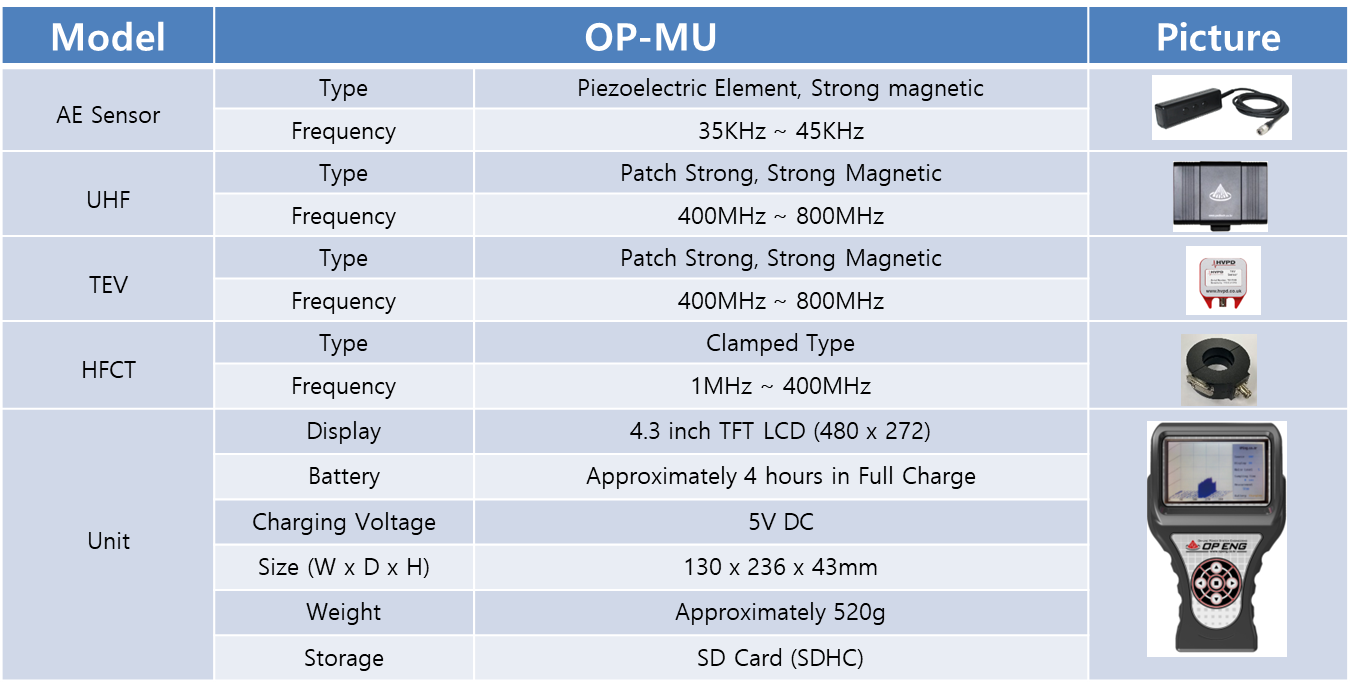

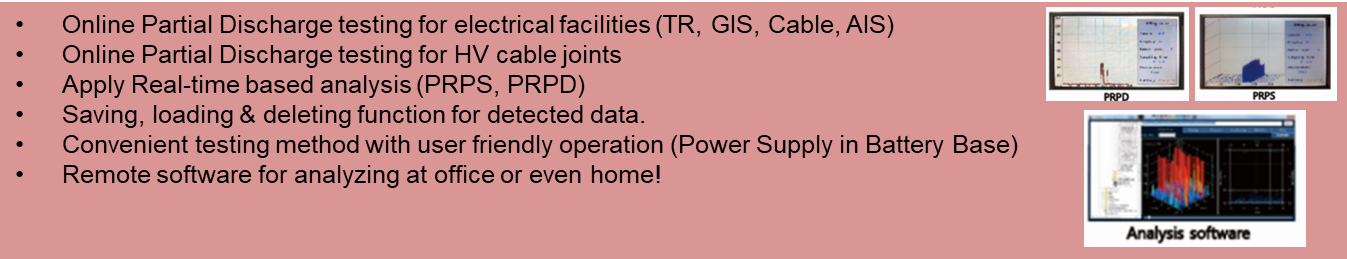

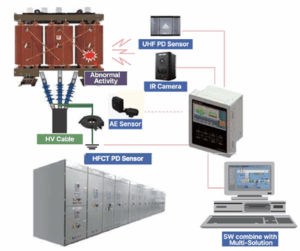

Portable Partial Discharge Unit (OP-MU)

Partial Discharge Online Monitoring System (OPM 400)

|

Ø Monitoring system to detect PD signal and temperature distribution chart for Mold Transformer, Circuit Breaker, Busduct due to its internal defects Ø Monitoring system to detect PD signal and temperature from HV Cable Head due to its defective insulation Ø Apply UHF & HFCT method to detect PD in real-time and display in PRPS and PRPD Ø Configure HMI and user-friendly based operating software Ø Display real-time wave-pattern at LCD to check the status at the site Ø Inbuilt storing function with 7.0 touch screen |

Cameras Monitoring System – IR , UV , Acoustic

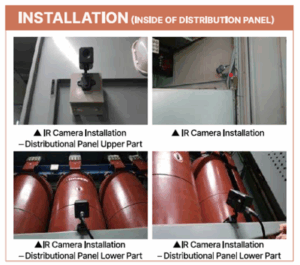

Infrared Rays Thermal Graphic Online Monitoring System (OPM-IR80)

|

Ø Data collection and control devices for industrial sites or building energy management system Ø Fire prevention by monitoring with infrared thermal images that may occur in LV distribution panel busduct and others Ø Monitoring system to detect temperature distribution chart for HV cable due to defective insulation Ø Able to measure temperature targets at least 5 points and express it to the max/min value |

MMI Monitor

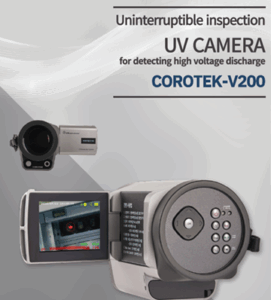

Portable UV Camera Unit (COROTEX-V200)

|

Ø Light and handy Ø Easy to use and convenient Ø Detect the corona stably at a close range (within 20m) Ø Low price compared to other expensive corona cameras Ø Easily determining the abnormality of electronic high-power equipment by displaying maximum amount of corona Ø Function of detecting the corona with beep sound Ø Recording and playing the situation in real time Ø Can be used for a long time with one charge, and Easy battery replacement Ø No degradation of detection performance for using SMI special sensor Ø Easy to repair |

|

Portable Acoustic Image Camera Unit (SMS-100)

|

SMS-100 uses microphone array beam forming technology to acquire sound source distribution data, |

Characteristics of the System

- 64 MEMS digital microphone arrangements provide accurate positioning.

- Detecting up to 100m.

- Select the request frequency range by user between 0 ~ 65MHz.

- 24-bit resolution with 7” LED.

- Possible to detect gas leaking and partial discharge.

- Provide photos in JPG or PNG format and take MP4 25FPS images for video clip

- Provide three languages (English, Korean, Chinese)

- Web-based automatic report generation.

- Simple structure for easy diagnosis and measurement

- Reliable noise elimination

- High performance data acquisition unit

- Customisable software design

- Generate report automatically